It is very important to correctly assemble the grinding wheels on the tool holder flange of the squaring machine, as, first of all, the correct assembly makes the operator safe and prevents damage to the structure of the machine and to the grinding wheel itself.

Furthermore, it facilitates the running-in of the grinding wheel, reducing its time and allowing the operator to enjoy the full potential of the tool in advance.

For this reasons PREMIER recommends paying maximum attention to the coupling of the grinding wheel to the spindle of the squaring machine, highlighting some important steps:

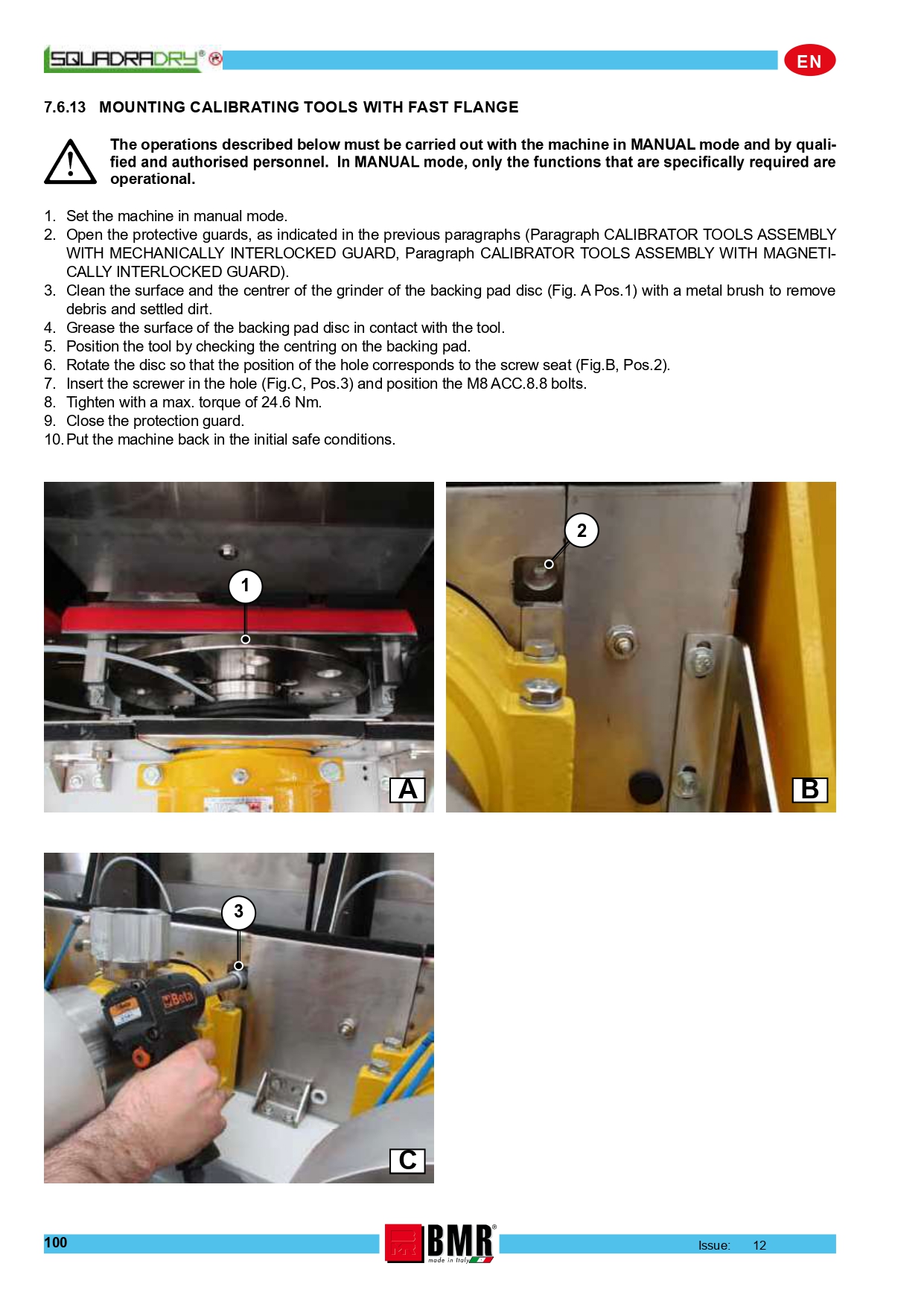

- Carefully clean the front part of the wheel-holder flange by removing impurities with a steel brush.

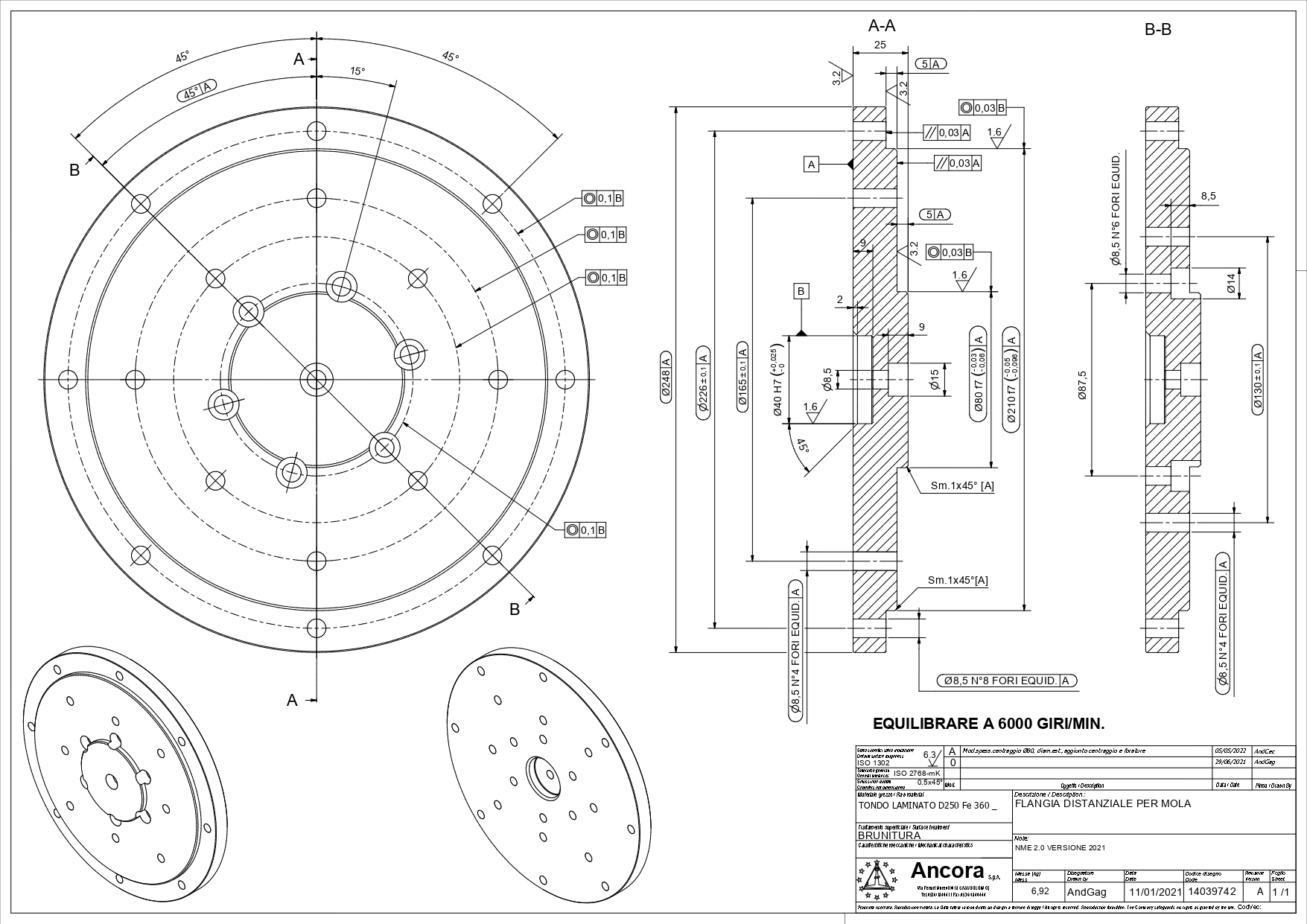

- Bring the PREMIER wheel close to the wheel-holder by coupling the central hole of the wheel with the wheel- holder centering flange.

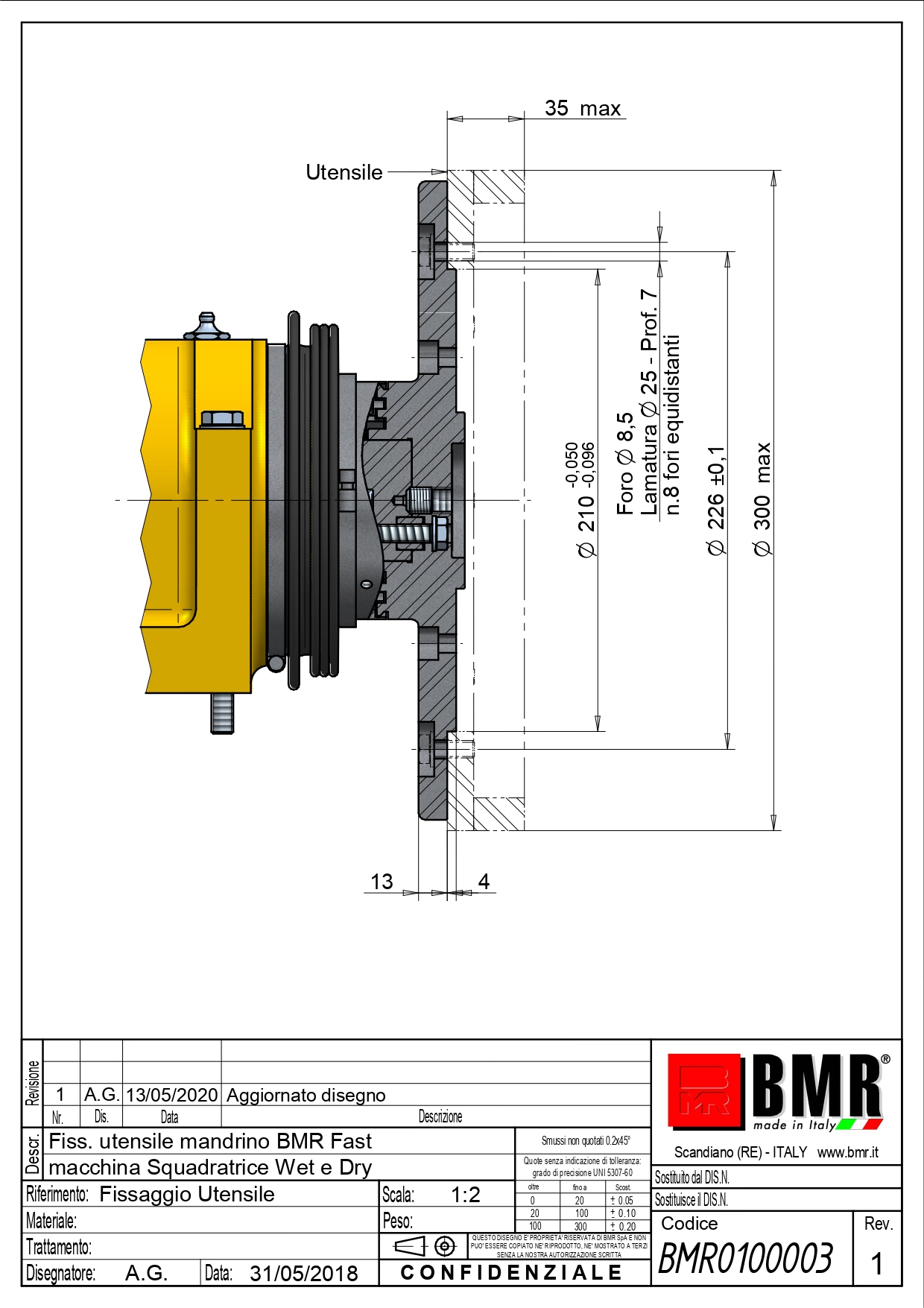

- Make the through holes of the wheel holder flange coincide with the threaded holes on the wheel's body.

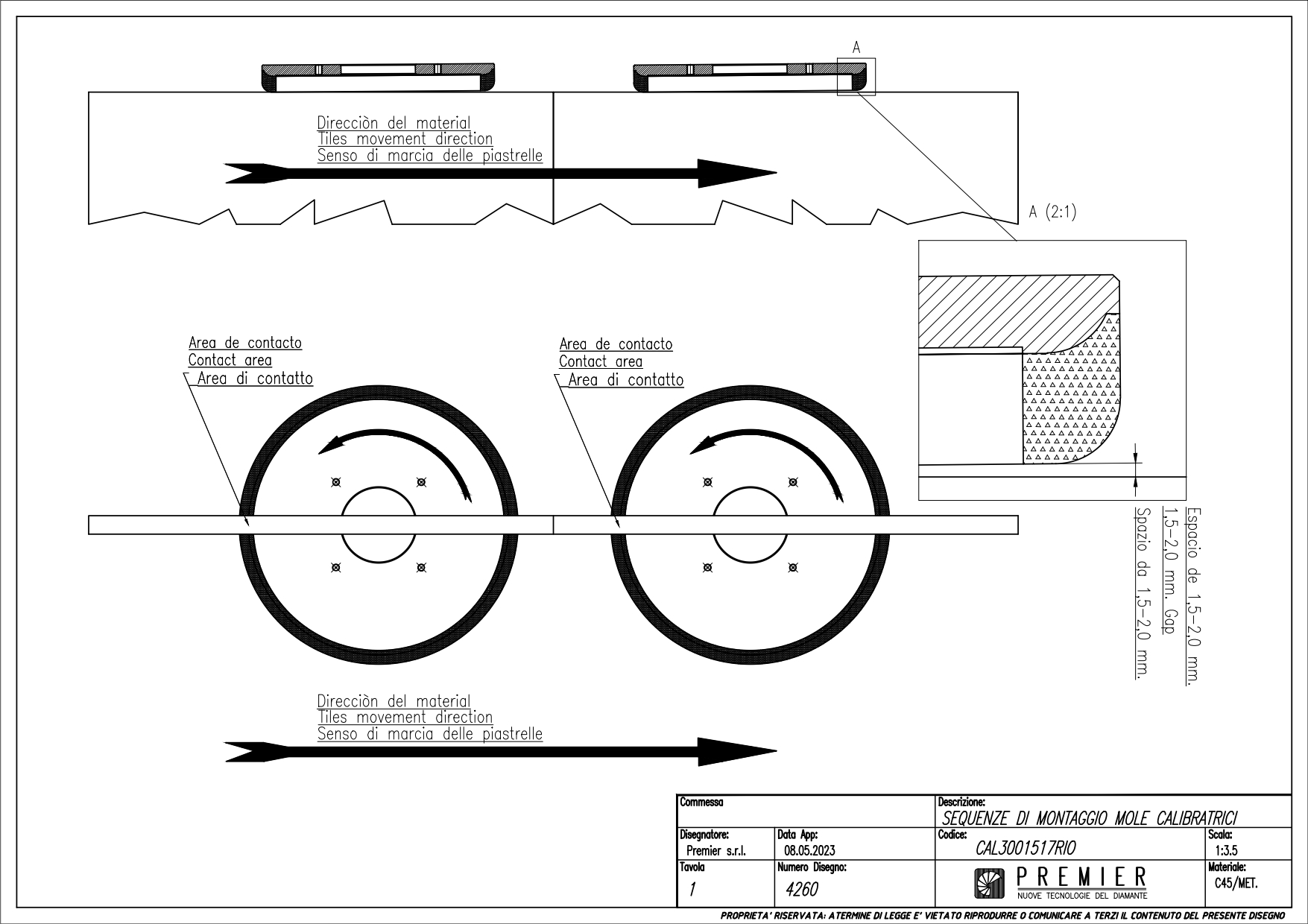

We remind you that the wheel must not be placed parallel to the material but inclined so that the contact with the material is only in one area of the diamond band (see drawing).

The contact must take place in the part of the diameter facing the entrance of the material and the direction of rotation of the motor must be such that the grinding wheels affect the tiles from top to bottom.

PREMIER recommends paying particular attention to the inclination of the grinding wheel respect to the tiles or slabs; the ideal inclination is when the distance between the point opposite the contact area and the edge of the tiles or slabs is approximately 1.5-2.0 mm (see drawing).

Excessive inclination of the grinding wheel leads to deformation of the band, creating an evident and deep serration in the edge of the tiles or slabs.

TOOL ASSEMBLY INSTRUCTIONS ON BMR SQUARING MACHINE

TOOL ASSEMBLY FLANGE ON ANCORA'S SQUARING MACHINE