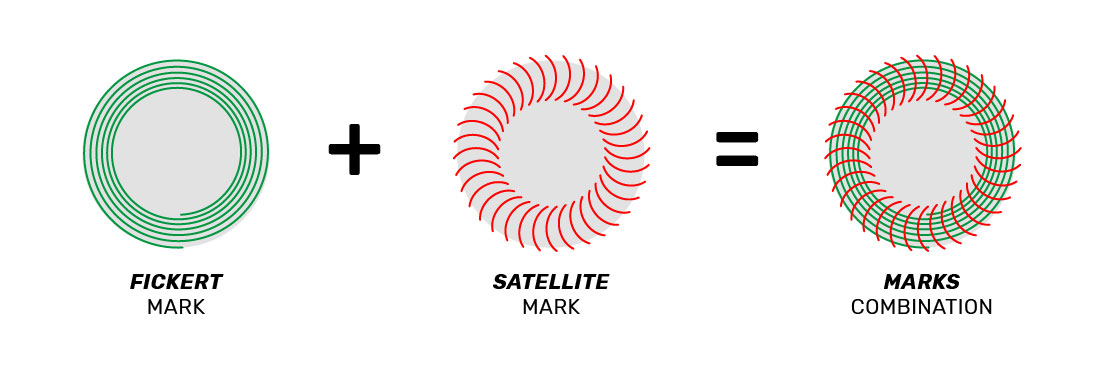

Premier has, for some time, been successfully experimenting with the use of satellite heads, and following a series of tests c/o the Lab, we have come to the conclusion that alternating the use of satellite and Fickert heads results in maximum tool yield and final product quality.

The reason lies in the fact that The mark left by the Fickert head (photo A) and consequently the trajectory described by the tools being machined consists of concentric circles, while the satellite head leaves curved marks (photo B), positioned radially with respect to the center of rotation of the head.

Photo A: mark of a Fickert head

Photo B: mark of a Satellite head

Photo C: drawing of the trajectories described by the Fickert (green) and satellite (orange) tools

Having finished testing in the Lab, we assembled c/o a long-standing customer, Lourdes SA ceramics, a lapping line alternating Fickert and Satellite heads, and the result was excellent.

- At the inlet, we have included 2 multi-diameter satellite heads that, thanks to the specific inclination of the tools, facilitate the inlet of tiles, reducing incoming edge breakage to zero, even overcoming height differences of 10 mm and spacing of more than 30 cm without problems.

- In the following, we alternated Fickert heads with satellite heads in order to achieve maximum tool yield and line productivity

- Following we have alternated Fickert heads with satellite heads, in order to obtain the maximum yield of the tools and the maximum productivity of the line.

In this way we have combined (drawing C), enhancing their qualities, the advantages of the satellite heads (versatility and productivity) with those of the Fickert heads (processing quality), obtaining a high quality lapping / polishing line capable of significantly increasing the speed and productivity of machining and the yield of the tools.

This sign alternation has a beneficial effect on the behavior of both tools because it helps to keep them always lively and with the cut always clean and open.

This effect especially benefits the Fickerts, which, working in a low-speed system, have a tendency to "close up"; by alternating them with satellites, on the lapping line, we greatly increase their durability. As a result, we reduce the width of the swing by minimizing the escape of the Fickert heads from the tile, gaining centimeters of processed material.

Increasing tool life generates two beneficial effects:

- Reducing production costs.

- Reduction in the amount of non-recyclable waste produced by the line, with a great benefit for the environment.

"Since we installed this line at Lourdes SA," explains Aldo De Stefani, our sales engineer responsible of the South America Area, "we have been processing large dark slabs with excellent results in terms of both quality and productivity! We have definitively eliminated the sign of progress, every lapper's nightmare and reduced the amount of non-recyclable waste produced, with a great benefit for the environment!"

PREMIER

Your Tooling LAB