PREMIER LAB.

The process of lapping and polishing ceramics is essential to give each tile a smooth and shiny surface. To optimize this process, it is essential to maximize productivity and, at the same time, reduce costs.

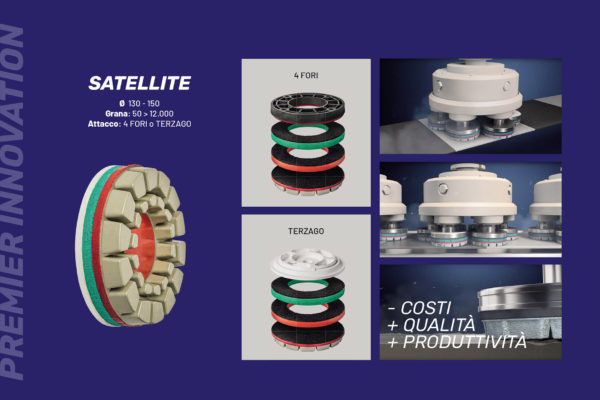

The satellite system can be applied to all honing machines and enables end-of-line operations such as roughing, lapping, honing and satin finishing.

What characterizes it is its ability to generate more kinetic energy than any other system in use, thehigh speed of rotation developed by the satellite (the 1,500 rpm) is transformed into kinetic energy capable of tripling the cutting power compared to the "classic" Fickert.

This translates into higher quality and productivity in end-of-line machining.

The benefits brought by the use of satellite are detailed below:

- contact area (about 25 mm) smaller than the Fickert (100 mm) allows tools to penetrate every depression for better finishing.

- the diamond satellite is modular, modular with several layers of Velcro or as a single block. The versatility and modularity of the tool allow it to change trim depending on the desired degree of flatness.

- For the same volume removed, finer-grained tools can be used; therefore, obtaining tiles without scratches and with a higher degree of gloss.

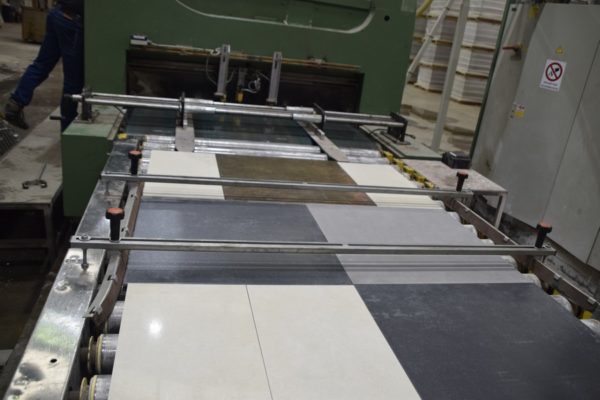

Premier's Proposal to increase lapping line productivity even more is the Parallel Row Satellite System developed by its Premier Lab.

Premier, with its special Satellite head, proposes to simultaneously process tiles that run in multiple parallel rows.

Two reasons support this statement:

- first, the Satellite Premier does not trowel, it rotates on itself and goes from tile to tile by rotating on an inclined axis, pushing the tile against the conveyor belt; therefore, there is no danger of lifting even while holding the tiles apart;

- secondly, the tangency line is 25 mm, divided over two rows of teeth, so the tool is able to penetrate all depressions, including those between juxtaposed tiles.

An option that would instead be impossible on sanding and lapping lines that make use of Fickert heads, it in fact, trowels left and right with a variable line of tangency to the tiles. In this its movement it can easily hook the side of the tile, lifting it up and damaging the entire tool set, the head, the tiles, and even the conveyor belt.

The application of Satellite Premier on tiles arranged in parallel rows was then studied within the Premier Lab, and the results of the study prove that such processing is indeed possible.

Add to this the technical features and advantages peculiar to the satellite system already described (rotational speed, developed kinetic energy, two rotary motions of head and tool), and the system's ability to improve the quality of the finished product, multiply the productivity of the lapping process, and significantly reduce costs per square meter is evident.

For 30 years a leader in the manufacture of diamond tools

Thanks to the engineering of production systems and constant technological upgrading, PREMIER guarantees timely delivery and 100% MADE IN ITALY quality.

Information & Contact