Premier has, for years, been successfully experimenting the use of satellite heads, and he finalized that, alternating Satellite and Fickert heads, you get the maximum yield of the tools and the maximum quality of the final product.

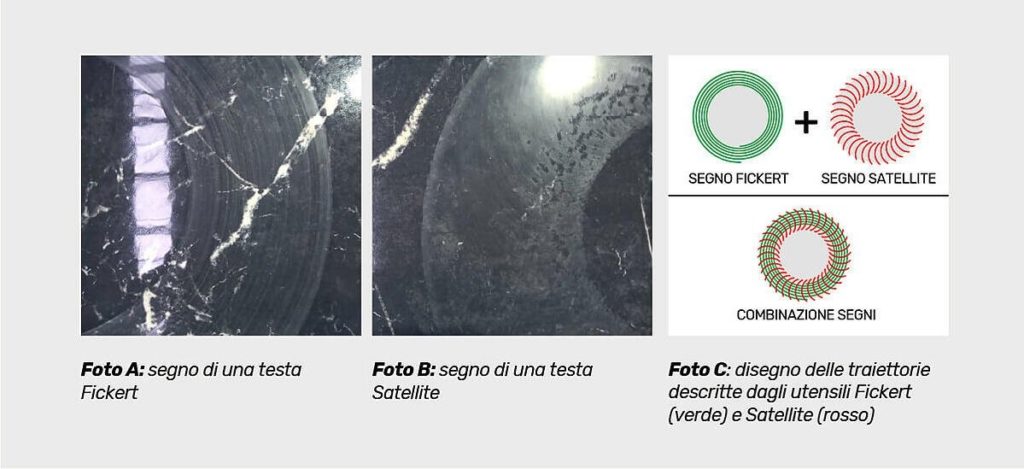

The reason lies in the fact that, The mark left by the Fickert head (photo A) and consequently the trajectory described by the tools being machined consists of concentric circles, while the satellite head leaves curved marks (photo B), positioned radially with respect to the head's center of rotation.

Thus by alternating, satellite and Fickert heads, any machining marks, instead of becoming evident due to the successive passage of equal tools are erased by the successive passage of tools describing a completely different trajectory (photo C).

By configuring the lapping line for large slabs, alternating Satellite and Fickert heads, numerous advantages are obtained:

Elimination of broken edges at the entrance of the slabs: by setting satellite heads in the first positions of the lapping machine, the risk of breaking the edges is reduced to zero.

The entrance of the slabs into the lapping machine is a critical phase, in presence of geometric irregularities, poor flatness, "raised beaks" or irregular geometry of the sides, Fickert head, with its sickle-like movement, parallel to the advancement plane, often breaks the edges of the slab, that must be wasted.

The satellite heads, on the other hand, are slightly oblique compared to the sliding plane of the slabs and have backward attachment points, so slabs entry is easier; moreover, the tools rotation allows to easily surmount even the most irregular edges.

For this reason we reached the target of zero breakage of the edges in the entrance.

Use of finer abrasive grains: the satellite, with the same removal, works with much finer grains, improving the quality of processing, especially of dark colors and completely eliminating the annoying cobweb effect in particular conditions of light.

High efficiency: the combination of the rotary motion of the head and that of the tool allow the satellite system to develop a much higher cutting speed, increasing its efficiency. The set up of satellite heads in the first two positions and two more in positions 5 and 6 of the lapping machine allows to increase the processing speed by 20%, thus increasing the productivity of the line.

In addition, the satellite high processing speed (triple compared to a Fickert head) allows better use of the abrasives, reducing costs by almost 20%.

Fincibec alternates satellite and Fickert heads on his large slabs lapping line, obtaining excellent results and eliminating processing waste.

PREMIER

Your Tooling LAB