Italian tile is also resisting price increases and logistical problems induced by the pandemic and the war in Ukraine. Saying so in a commentary are Savorani, Tioli, Fabbri and Verdi, whose statements are reported in an in-depth Ceramic World Web feature.

The first major contribution comes from Giovanni Savorani, president of Confindustria Ceramica. The ongoing conflict and the unknown about the cost and supply of raw materials threatened to be the "perfect storm" for Italian tiles. This was because most of the cheap gas came from Russia and, from the Donbass, some 2 million tons a year of clay, which was essential for production, was arriving.

However, despite the premise, the market still offers reassuring signs. For President Savorani , "Not only are we all working at full speed today, but we are amazed at the response of customers; we have not lost an order despite the 10 to 20 percent increase in price lists, which is necessary to recover at least part of the price increases."

The procurement of raw materials

Despite the scenario of a few months ago, the feared failure to supply raw materials did not occur. For Villiam Tioli, president of Caolino Panciera, "Already in April the first Turkish ship loaded with clays, kaolins, and feldspars to replace Ukrainian materials for mid-range production docked at the port of Ravenna, and four more will arrive by September; while for high-end products, i.e., slabs, for which we need top-grade materials, the first ship from India left these days and we have already scheduled a second one."

While companies have succeeded in securing "alternative" supplies after the Donbass crisis (which in any case will not be resolved anytime soon, because the infrastructure would still have to be restored), there are still problems and difficulties. In particular, "not only because Indian clays cost much more and the euro-dollar exchange rate is further exacerbating our costs, but because Turkish producers and government are also beginning to pull back in the face of increased demand, imposing new export permits, rationing supplies and raising prices."

The price of gas

Logistical difficulties also persist on gas prices. For Roberto Fabbri, president of the ABK group, "We managed to find clay of similar quality to Ukrainian clay in India, but it cost us 40 percent more, and as long as the cost of methane gas remains below 1 €/mc we manage to work with non-negative margins. The problem is if a complete import blockade from Russia is triggered, because we have calculated it would mean a gas cost of 1.5 €, which is unsustainable for energy-hungry industries like ceramics, with catastrophic consequences for the district. For another 6-7 months, Russian gas is indispensable."

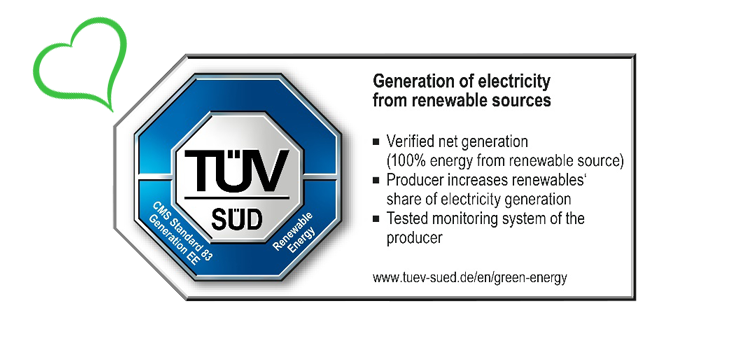

On the other hand, a response is expected from the government to handle this issue. For Graziano Verdi, "What we expect from the government is that it will keep its commitment to reserve 30 percent of the national gas for gasivorous and energy-intensive companies at the market price, with an advance of 250 million euros, of which the country would return quickly, because extracting gas in our Adriatic costs 5/6 cents/mc account the current market price of 1 euro (and the 25 cents a year ago). In our group we had hedged gas prices so we were able to preserve margins. In addition, we are completing targeted investments, first in a cogenerator and now in 2 MW of photovoltaic roofs on the Rubiera plant to be totally self-sufficient for the electricity part."