Dry squaring always presents many pitfalls. In addition to possible errors on the part of the operator, who often works manually, exponential increases in tool temperatures as the required stock removal and/or production speed increases are primarily the cause of major problems.

What can happen in these cases is tile breakage, constant operator interventions, machine downtime with consequent elevation changes due to tool cooling, and generally low productivity. This happens because, with high temperatures, committed tools expand and require new adjustments to get the machine back up to speed.

A difficult balance to find

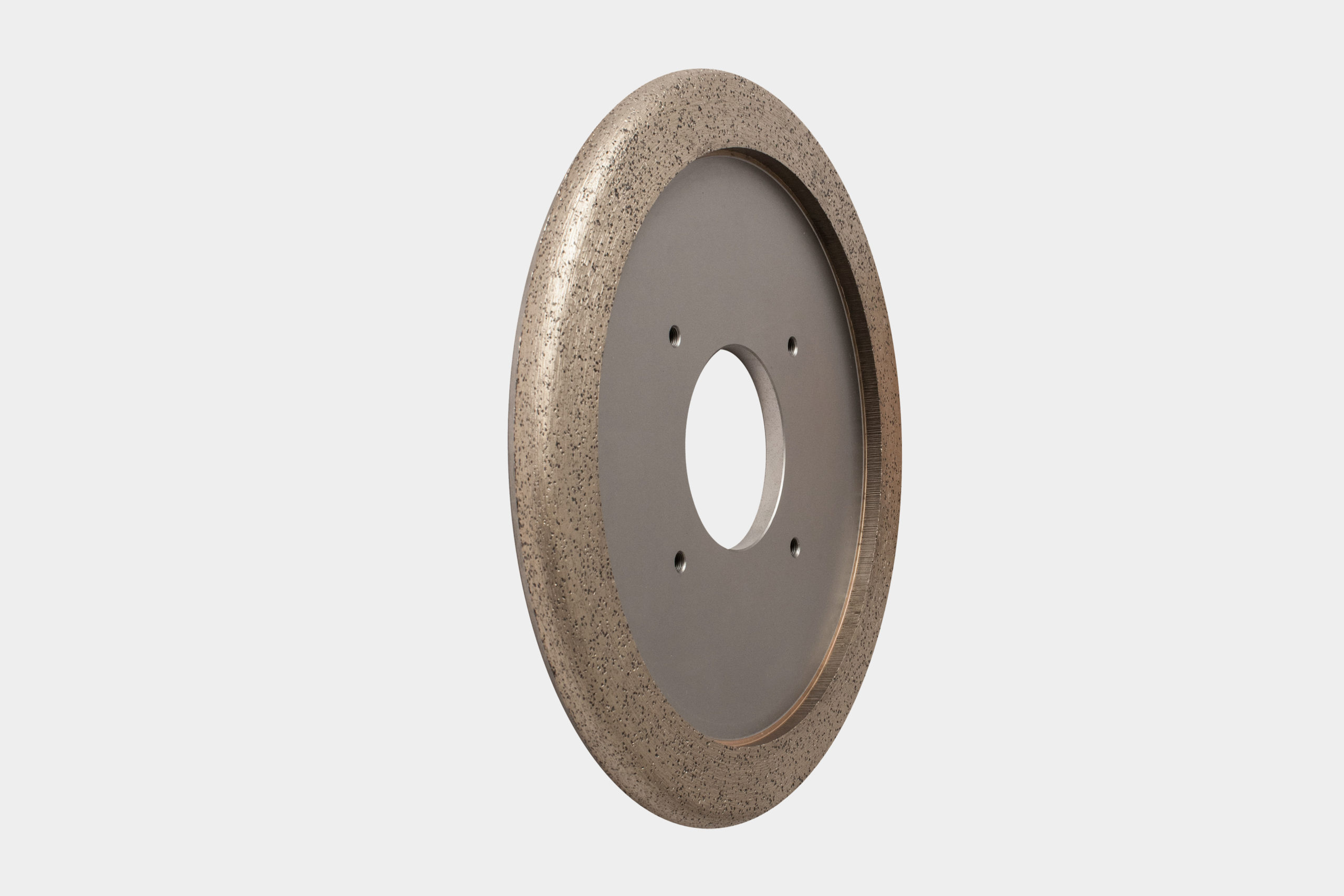

Removing without force and ensuring long tool life is a difficult setup to find.

It is a constant search for the balance between alloy renewal (i.e., the ability of the alloy to replace diamond bits that have already worked and lost sharpness with newer, sharper ones) and the need not to increase consumption of the alloy itself, thus extending tool life.

Premier, in its research laboratories, has developed an alloy that optimizes the balance between durability and tip renewal, with the goal of providing greater sharpness.

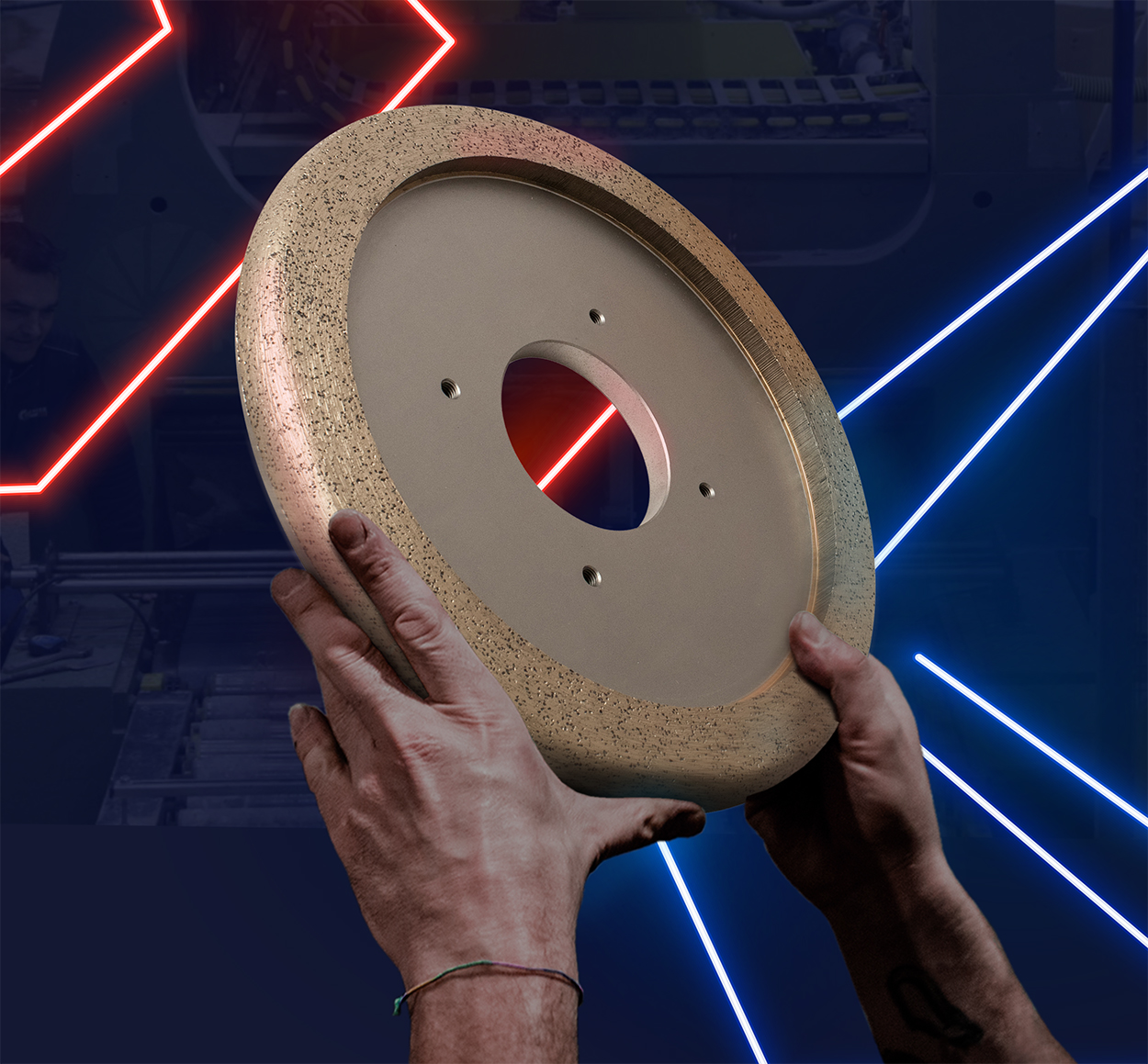

Premier League B6

Premier's Alloy B6 was thoroughly tested in our lapping and squaring facility in Alcora, Spain, where it was brought to expression under the most extreme conditions and brilliantly exceeded all expectations.

Even under extremely demanding conditions for any tool, such as squaring materials as thick as 3 cm, Premier's Alloy B6 proves stable as temperature increases, does not expand, and can guarantee the same size in both hot and cold conditions.

Aries and Marathon

This alloy is finding favor with those who use it in the Aries and Marathon shapes and is widely used in the middle part of the line, considered by many to be the most difficult part of dry squaring, an activity that comes immediately after roughing and before finishing.

With the introduction of Premier's B6 League, machine utilization stabilizes at its full potential, maintaining 100 percent first choice and minimizing or even eliminating operator intervention.

Premier's Alloy B6 gives you: cold removal, excellent durability, elimination of breakage, increased and stabilized productivity.