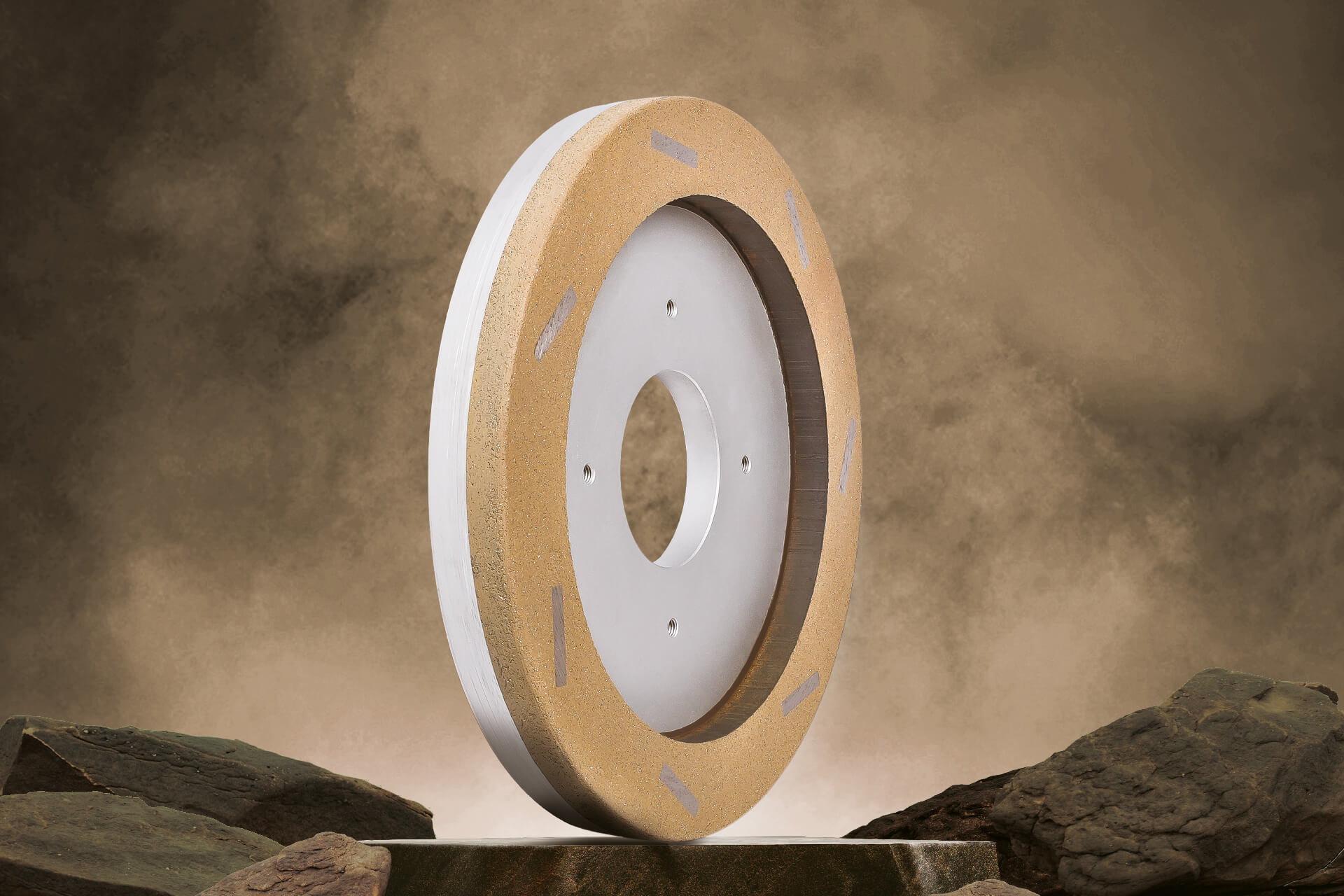

TECNA 2022 will be the first post-pandemic exhibition in presence and PREMIER is ready with a novelty that we will show during the event: the SPIDER DRY, the latest dry grinding wheel, born at PREMIER's. It differs from the other wheels because it adds the metal wheels characteristics of productivity and abrasion to those of precision in the finishing of the resin wheels!

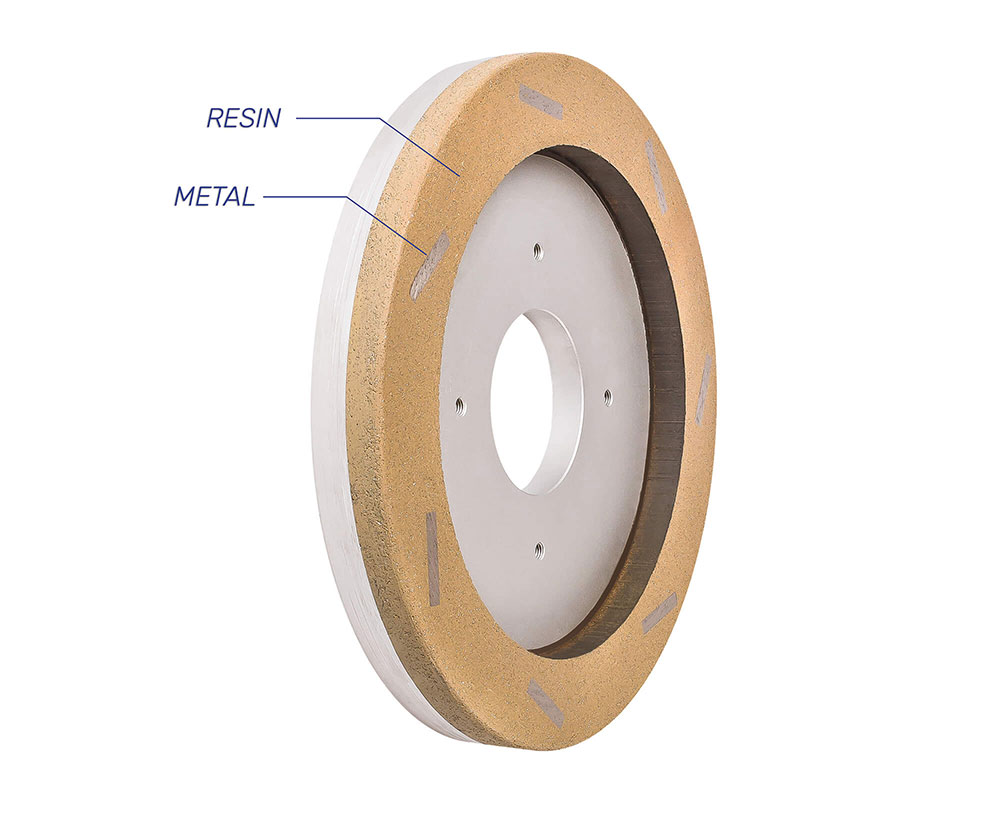

The SPIDER DRY consists of a diamond resin base, coupled with sintered metal inserts that greatly increase its duration and productivity.

These physical characteristics and the special geometry of the grinding wheel allow it to work both by abrasion (the diamond resin part) and by milling (the sintered metal inserts), in a discontinuous manner and this means that the grinding wheel never overheats while working.

The SPIDER DRY has a lot of strenghts, which make it a real innovation for the industry, we list the most important below:

- Easy to use: it does not require running in, because the surface layer is of diamond resin, so the wheel easily adapts to the geometry of the squaring machine.

- Reliability :

- The resin-metal combination and the calibrated geometry of the wheel eliminate the possibility of accidental breakage of edges and corners

- Reduced heating of the wheel even during roughing and therefore no thermal expansion problems

- Energy saving and environment: It absorbs less energy with the same removal, as the metal inserts work discontinuously.

- High productivity e duration: the presence of the metal inserts means that the productivity of the grinding wheel is at the same or higher level than a standard metal one.

- Versatility: the same wheel (by varying the grit: Giga or Mega) can be used in all roughing and semi-finishing positions of the squaring line.

The PREMIER team will be happy to provide you with any further information you need and invites you to visit us at TECNA in Rimini from 27 to 30 September 2022 (Hall B3 - stand 076).

PREMIER

Your Tooling LAB