In recent years, the "lappato revolution" has led more and more ceramic manufacturers and subcontractors to dismiss the polishing plants complete with calibration, necessary to process the porcelain stoneware tiles.

Today, because of the obvious technical limits of glazed and lapped slabs and tiles where floors are subjected to stress caused by high levels of foot traffic, many clients have decided to return to gres porcelain. and thanks to the new solutions that the paint-factories are proposing to the most innovative ceramics, many customers have decided to go back to the stoneware, therefore, the need to polish this type of tiles or slabs is reborn.

Faced with the need to polish technical stoneware, some important ceramic manufacturers have turned to Mirror, a historic end-of-line subcontractor operating in the Sassuolo area, also known for being among the first to experiment the "super treatments", so widely used today in end-of-line departments.

The latter, however, had also dismissed its calibrating machines, so it contacted PREMIER, its historical supplier, in search of a system that would allow it to polish slabs and tiles, avoiding the use of the bulky calibrating machine.

As a team, Mirror technicians: Luca Buzzoni and Tiziano Nordi and PREMIER technicians, strengthened by their previous experience in Coop-Imola, where they contributed to polishing the full-body tiles presented and awarded at Tecnargilla 2018, studied the applicability of metal satellites on an existing lapping-only line, transforming it into a line capable, thanks to a single tool change, of polishing technical porcelain tiles and lapping glazed tiles.

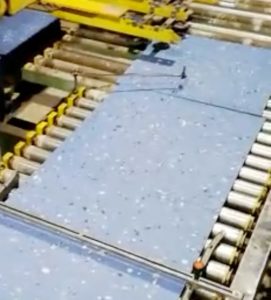

By applying the PREMIER satellite heads to a lapping line, the first "Levi-lapping" machine capable of calibrating/polishing and lapping just by changing tools was born!

In addition, thanks to the new rapido couplings developed by PREMIER, tool changeover time is drastically reduced..

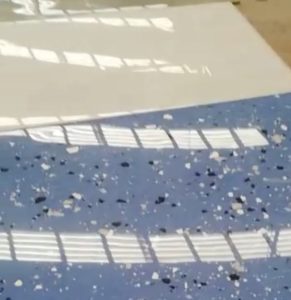

On a line of 30 heads, such as the one in Mirror, we can polish 600 mm format technical porcelain tiles at a speed of 3 / 3.5 meters per minute, obtaining an excellent degree of polish, and then, on the same line, without intervening in the mechanics of the line, but only replacing the tools, we obtain an efficient lapping machine that, thanks to the satellite heads, guarantees an increase in productivity and a 15-20% cost saving compared to an all fickert line.

On a line of 30 heads, such as the one in Mirror, we can polish 600 mm format technical porcelain tiles at a speed of 3 / 3.5 meters per minute, obtaining an excellent degree of polish, and then, on the same line, without intervening in the mechanics of the line, but only replacing the tools, we obtain an efficient lapping machine that, thanks to the satellite heads, guarantees an increase in productivity and a 15-20% cost saving compared to an all fickert line.

These results have been achieved thanks to the deep commitment of the Mirror/PREMIER technical team, who have done a great job of refining the machining parameters and have obtained an optimal polishing quality.

Thanks to the introduction of the "Smoothing-Lapping" machine, Mirror has become the main "polisher" of technical porcelain tiles, for the most important ceramic tile manufacturers in Sassuolo, without any enlargement of the lines and without making any new and costly investments.