Since its creation, Premier has focused all its energies on research and innovation.

The heart of our work is the constant pursuit of excellence, to ensure that those working in the world of ceramics use state-of-the-art tools that can also make a difference in the marketplace.

It was from this philosophy that two of Premier's most important creations were born: Spider Dry and Orbiter.

Let's look at them together.

What is Spider Dry?

The Spider Dry is the latest dry grinding wheel designed in our laboratories. It differs from the others because it combines the productivity and abrasion characteristics of metal grinding wheels with the precision finishing characteristics of resin grinding wheels.

The grinding wheel consists of a diamond resin base combined with sintered metal inserts that greatly increase its durability and productivity.

Why choose Spider Dry?

There are several reasons to choose our latest dry grinding wheel. The benefits it offers are many, chief among them versatility. In fact, the Spider Dry can be used in all roughing and semi-finishing positions of the squaring line. In addition, it is extremely easy to use and is programmed for long life and low wear over time.

Also of note are the benefits in terms of energy optimization: the grinding wheel absorbs less energy for the same amount of stock removal, as the metal inserts work discontinuously.

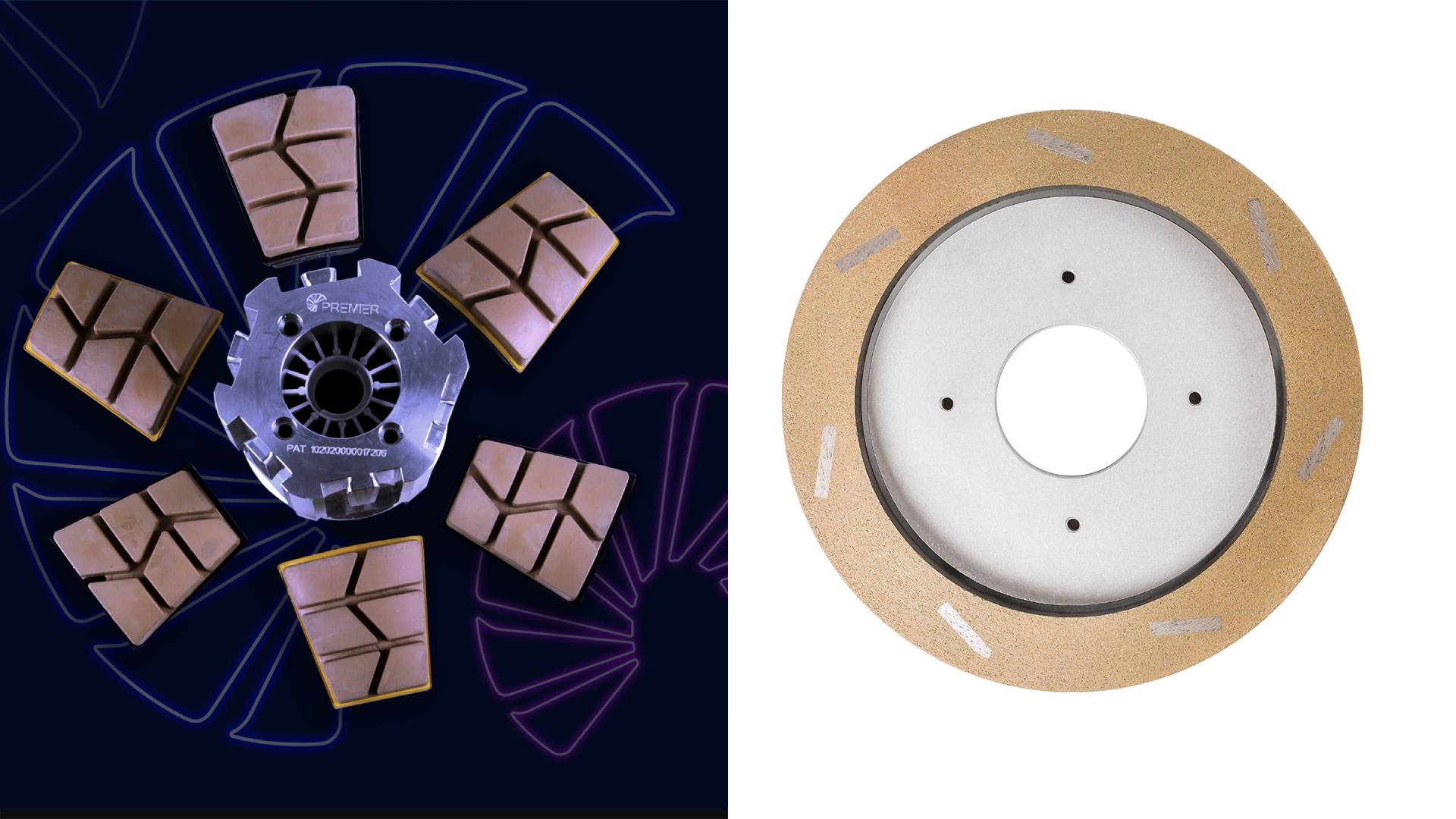

What is Orbiter?

Orbiter is Premier's innovative tool that can turn a cylindrical head into the most powerful and precise lapping system ever, thanks to 2.5 times the cutting power of a Fickert head.

Orbiter consists of 5 cylindrical tool holders equipped with 6 tools each, mounted on the shafts of a standard cylindrical head; these are arranged radially and describe a circular trajectory with a radius of 110 mm.

What are the advantages of Orbiter?

The benefits of Orbiter are many, first and foremost the simplicity in its use: assembly is very quick. In addition, Orbiter was created to ensure maximum durability: each head is equipped with 30 tools, so it will be possible to increase line speed with much rarer tool changes, all to the benefit of productivity.

Another big advantage, as we mentioned, is the cutting capacity: tangential speed of Orbiter is about 27 m/s versus less than 11 m/s of a standard Fickert head.

Rounding out the picture is the great versatility of the instrument and the quality of the final work obtained.

If you would like to learn more about Premier products and get detailed information from one of our consultants, contact us now.